If you know your industry inside out, you’ll know that big ambitions in manufacturing, logistics, retail or utilities mean harnessing automation to seize the opportunities of digital transformation. That’s fine, because you understand your sector and have an affinity for the digital services that will unlock operational efficiencies and new business models. But that’s not the end of it. Industrial digital services need the lifeblood of wireless connectivity – and not all wireless connectivity is the same. It’s time to get up to speed with private 5G networks.

Across the world, spectrum is being released to enable private 5G networks that have the potency to create use cases that have never been seen before. This is why I urge my contacts to become as network savvy as they are industry savvy. Our recent ‘Mobilizing private 5G networks’ whitepaper is required reading as far as I am concerned, because it carefully unpacks how to deploy a private 5G network for maximum business impact.

I’d like to share its value with you – from the perspective of digital services innovation. We have many clients here at Cambridge Consultants who express a vision for the digital transformation of their facilities and estates.

Mobilizing private 5G networks

The new retail experience of the Connected Store, for example. This is not just about human shoppers using smartphones, it’s about digital shelves, shelf-replenishment robots and smart shopping trolleys. Then there’s the Connected Factory, with new operational efficiencies, and the new visitor or fan experiences of the Connected Venue. And I should also add Connected Processing Plants and the autonomous operation of complex and critical infrastructure seen in the utilities industries.

These ‘Connected X’ labels are generally expressions of new experiences for people and ‘things’ as abundance of bandwidth and access to cloud-based resources are leveraged. This provides the means to augment the human experience or improve the reliability and operational performance of connected ‘things’.

While wireless connectivity has been an important element of digital transformation, the very fact of connecting something without any business or end user context does not necessarily lead to a better experience for end users. Nor does it add up to better business economics, particularly with the higher cost of 5G modems, and the huge number of connected end points in an industrial setting. It is essential that there is a clear rationale relating it to both the digital strategy and the business case.

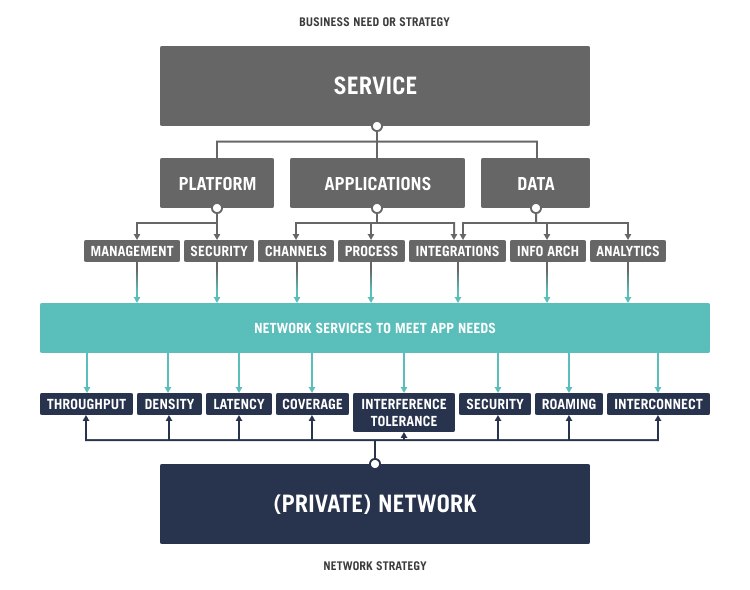

Innovative digital service design provides the tools to determine the end-to-end technology and business solution, as well as the requirements needed to feed into the 5G networks consideration framework. The whitepaper points the way for ambitious innovations to make the strategic connection between their overall business goals and the services that they require from their private network.

In the industrial setting, we talk about Industry 4.0, digital plants and smart machines. In utilities we see new digital trading processes and autonomous digital infrastructure inspections. Uniting all industries is a desire for digital supply chains. If you are a Chief Digital Officer (CDO) or Chief Technical Officer (CTO) charged with bringing about the transformation, then we need to talk about digital services technology.

Realising digital services

In essence, this is the intertwining web of business and technology that delivers on the end user goals of the people and systems in your ecosystem. Digital services are realised in the connected things; the digital surfaces across devices, web, mobile and voice; the software applications and processes; the flexible IT and communications infrastructure; and the overall service wrap that allows everything to be provisioned, operated, and managed.

We always start with the ambitions and business realities of an industrial enterprise. Typically, they are driven by the needs to offer ground-breaking changes in efficiency and productivity while at the same time delivering on the triple-lock associated with sustainability: people, planet and profit.

This triumvirate ensures that we consider the safety of people and the optimum use of industrial resources. Also, with a watchful eye on digital forces, an industrial organisation needs to protect their position in the supply chain to ensure they are not disintermediated by others and that they are keeping ahead of competitors.

The digital service needs to fulfil these ambitions but then will provide the means to:

- Integrate all the elements of system, for example from vibration sensor to pre-emptive robotic machine repair and autonomous loading of a ship at the dockside

- To define and optimise the interfaces between people and machines – machines augmenting operator activities and machines respecting the safety of people working with them

- Integration of the systems within the supply chain, for example connecting an end user in a Direct-to-Consumer (D2C) purchase to deliver a consumer’s personalised version

- A constant feedback loop, assisted by AI/machine learning, to continually learn and so improve the operation of the system

- Determine the business model to ensure there is new value being created and all the insights of from the system are correctly valued

The consideration of all these dimensions is the remit for digital service design. Designing the service to bring about the digital transformation of the factory, the plant or the port operation. The design provides the trajectory for the technology directions and vendor choices.

Bridging the requirements gap

From the service design we can determine the design of the system, which can be distilled down to three key components:

- The service platform

Realisation of the business model, the service wrap, the operations and maintenance, the APIs, the system integration and the digital channels (device, mobile, web, voice) - The applications (that run on the platform)

The business control and process flows, the application logic in the core, the AI based models, embedded in the devices and run as end user apps - The data

The content and control parameters, the collected data from devices, the meta data (‘data exhaust’) of how the service is operated. Also, the insights that are drawn from the data

My network design colleagues identify four characteristics of private 5G networks that can be provided and in an off-the shelf solution might require some trade-offs.

- Higher density (leading to greater capacity)

- Lower latency

- Improved coverage (of a space)

- Interference tolerance

By completing the service design for the business strategy and then translating that into the need of the service platform, applications and data, we can determine the exact need from these characteristics.

What our experience has shown is that sometimes the trade-offs from commercial off-the-shelf wireless networks are too stark. To achieve the desired digital transformation, we need to have an optimised or customised network to provide the right answer.

Where next for industrial digital services?

The power of abstraction is a powerful concept in computer science… the ability to utilise the services of a system by using well defined interfaces, but without having to know or care how the facility is realised. In many ways digital applications and services has relied on this abstraction in their dependency on connectivity and specifically wireless connectivity.

But reading the whitepaper is an eye-opener to the fact that we need to take a more informed approach to understanding the actual connectivity we need for industrial digital services. In short, to ensure we can produce effective, economic and truly transformation industrial digital services, we must understand the connectivity needs of digital services in more detail. We also need to we are making the right decisions in choosing the wireless connectivity. As I say, less abstract and more network savvy.

The next step? I do recommend you read the report, and perhaps follow it up with some insight into digital services.

Do please feel free to contact me directly to continue the conversation. I think uniquely for one organisation, Cambridge Consultants has the integrated skills to harmonise the physical robotic and autonomous systems of the modern industrial infrastructure with the opportunities of innovative digital services. And then combine all that with the wherewithal to determine the design and potential customisation of a private 5G network.

専門家

Martin specialises in helping international clients realise their ambitions through the business application of transformational new digital services that leverage AI, immersive UX, Web3, cloud computing and ubiquitous networks.